Counter Flow Cooler

Counter Flow Cooler

After cooling, the granules temperature is not higher than the indoor temperature +3 - +8.

It adopts unique blade wheel discharging device. The unique pore plate increases inlet air size. It has smooth discharging and even baiting. It improves classifying and screening effect. Complete discharging helps to avoid cross contamination.

Counter Flow Cooler has access door on one side, which is easy to maintain. The organic glass inspection window is convenient to observe the inner material at any moment

It has stable and reliable performance and is suitable for various particles cooling.

The cooling of granule is an indispensable process in pelletizing section.The counterflow cooler can cool the granule material from the granule maker at the temperature of 70℃ ~ 90℃ to 3℃ ~ 5℃ slightly higher than the room temperature, and reduce the moisture content by ≥3%, which can ensure the quality of the granule feed in the process of packaging, transportation and storage.

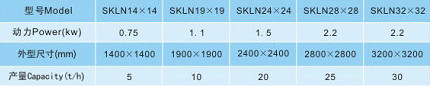

The output of counter-current cooler varies with different models, and it can be used in feed mills of various sizes.

Performance Characteristics

Counterflow cooler is the current international popular a kind of new type cooler, it is to use the principle of counterflow cooling high temperature, high humidity, particles of material for cooling, the environment air cooling vertically through the material layer, wind direction contrary to the direction of material flow, the first contact with cold material phase, gradually becomes hot cooling air into contact with hot material, make the grain forward gradually cooling, thus can avoid direct contact with high temperature granular material, because of the cold wind make particle caused by quenching of particle surface cracking.Because the cold air enters the cooler omni-directional from its bottom, the air inlet area is big, the cold air utilization ratio is high, therefore, the cooling effect is remarkable, and the machine energy consumption is low, the automation degree is high, the operation is simple, so the counter-current type cooler is superior to the previous vertical, horizontal type cooler new product.